Certification of Welding Personnel

-

Certification of Welding

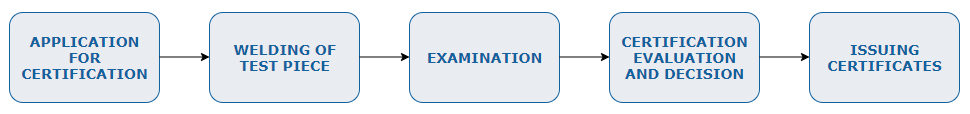

Personnel - Certification Procedure

-

Material and Shape

of Test Pieces - Welding of Test Pieces

-

Issuance of Certificate

and Certified Personnel - Frequently Asked Questions

- Inquiry Form

Qualified and tested personnel is key to quality products. Even more so when it comes to joining, where manual skills of an individual are crucial. And that is the reason why certification is of such importance.

Q Techna certifies:

- Welders

- Welding operators

- Brazing personnel

Welding procedures for which Q Techna provides certification of personnel:

- All procedures for metal welding(manual arc welding, MIG/MAG, TIG, SAW, oxy-fuel welding, laser welding…)

- Brazing

- Thermoplast welding

Standards applicable for certification of welding and brazing personnel:

- SIST EN ISO 9606 series

- SIST EN ISO 14732

- AD-2000 HP3

- SIST EN ISO 13585

- ASME B&P Code section IX

- DVS 2207

- SIST EN ISO 17660 series

- DVGW VP 614

- SIST EN 130670

When a customer needs to certify welders following:

- AWS D 1.1

- AWS D 1.6

- ASME B&P Code section IX

We carry out all necessary destructive and non-destructive examinations and prepare the certificate form. The latter is approved by the welding organisation itself, as that is a second-party certification.

mag. Ambrož Rožman

+386 7 49 12 419

+386 41 215 267

ambroz.rozman@qtechna.si

atestiranje@qtechna.si

Milan Javornik

+386 7 49 12 431

+386 41 559 706

milan.javornik@qtechna.si

atestiranje@qtechna.si

Andrej Weiss

+386 7 49 12 439

+386 31 719 834

andrej.weiss@qtechna.si

atestiranje@qtechna.si

Tamara Tomše Mavser

+386 7 49 12 454

+386 51 384 563

tamara.tomse@qtechna.si

atestiranje@qtechna.si

Jernej Zofič

+386 7 49 12 454

+386 31 818 037

jernej.zofic@qtecnha.si

atestiranje@qtechna.si

Material and Shape of Test Pieces

In case you prepare your own welding test pieces, pertinent certificate type 3.1, or higher apply.

Filler material requires certificate type 2.2, or higher.

Test pieces for welder certification against SIST EN ISO 9606-1

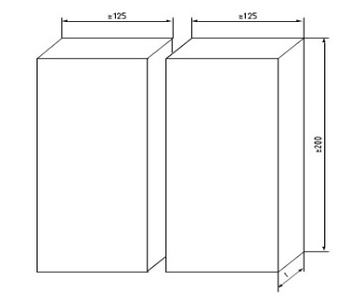

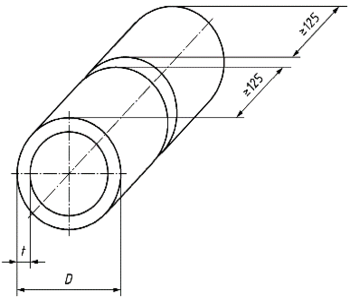

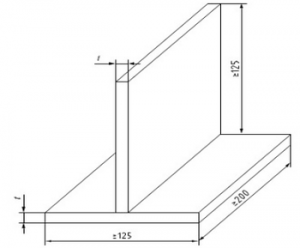

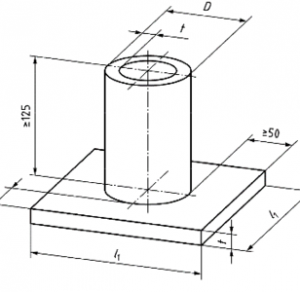

Dimensions of test pieces (mm) to be used for the purpose of certification pursuant to the standard SIST EN ISO 9606-1:

- Welding of butt weld in a plate

- Welding of fillet weld in a plate

- Welding of butt weld in a tube

- Welding of fillet weld in a tube

Presented in the following drawings/figures:

Welding of Test Pieces

WPS

Welding is carried out in accordance with the welding procedure specification (WPS), prepared by a customer. Q Techna can provide the support you may need.

Where does the welding of test pieces take place?

To achieve optimum results we recommend that the test pieces be welded on customer's premises under our supervision. Thus welders work in their own environment using their own equipment.

Q Techna professionals will assist you in the preparatory phase of certification tasks for the range to best suit your production.

Issuance of Certificate and Certified Personnel

Upon the fulfillment of all standard requirements a certificate is issued; its expiry date is defined by a reference standard.

A list of certified personnel may be obtained on request at info@qtechna.si, or through online inquiry.

Frequently Asked Questions

What is the renewal period for welder certification against SIST EN ISO 9606?

3 (three) years

How long does it take to obtain the certificate?

The certificate is issued within 10 (ten) days at the latest, following the welding of samples/test pieces, or earlier, if so agreed.

What is the manner to define exact requirements for certification range?

The entire range is specified in the certification requirement on a form provided for the purpose.

What are the key variables that dictate the range of the certificate?

They are as follows: the welding procedure; type, thickness and shape of base material; type of filler material, welding joint type (butt/fillet), welding position, welding from both sides (bs), (i.e., with material backing), or with no material backing.

Does certification for butt welding cover also fillet welds?

In compliance with the last revision of the standard SIST EN ISO 9606-1:2013 the above is no longer the option. To comply with the requirements for fillet welding, an additional fillet weld must be performed on a test piece.

What is the certificate range pursuant to SIST EN ISO 9606-1?

It is stated on the certificate.

How to determine certification and accordingly the certificate validity?

The baseline are welds (zvarjenci) formed in production. Should you need any assistance, you may contact us, sending us drawings with welding process description, or call us.

How do we (get to) know what the certification cost is?

On the basis of your request we make you an offer.

How do we submit a request?

You can do it in a number of ways: through mail, e-mail, using online application on the first page for the area in question, by phone or in person.

Inquiry Form

Head office

Q Techna d.o.o.

Cvetkova ulica 27

SI – 1000 Ljubljana

Slovenia

T: + 386 1 42 04 390

info@qtechna.si

Branch office

Q Techna d.o.o.

Krško branch office

CKŽ 135E

SI – 8270 Krško

Slovenia

T: + 386 7 49 12 470

info@qtechna.si